Back

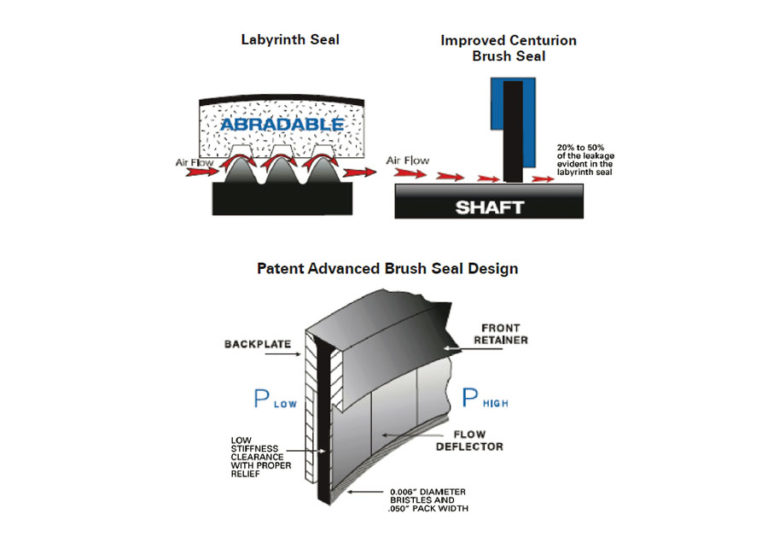

A Better Alternative To Labyrinth Seals

Eaton’s Centurion Improved Brush Seals are very high tip speed, high temperature seals, usually applied in the secondary and tertiary flow paths in gas turbine engines, capable of surface speeds up to 1,100 f/s (feet per second) and withstanding temperatures up to 1,200°F (648°C). As a replacement for labyrinth leals, brush seals evidence 20% to 40% less leakage while their bristles are in optimal condition. In addition, Centurion Improved Brush Seals weigh far less than labyrinth seals and take less axial cavity space.

Eaton’s Patented Design Increases Bristle Life

Eaton’s patented design holds the bristle pack in place, preventing deformation and stiffening, common problems affecting the longevity of the traditional brush seal. This design allows the seal to last longer at an optimal sealing performance than ordinary brush seals.

Benefits for using the Centurion Improved Brush Seals

Capability Ranges

Operating Pressures: 100 psid (690 kPa) per stage

Temperature: Cryogenic to 1,200°F (650°C)

Surface Speeds: Static to 1,100ft/s (335m/s)

Radial Excursions: Up to 0.030in (0.76mm)

Sizes: 2 in. to greater than 40 in. (.05-1.0 meters); larger diameters for segmented seals

Brush Seal Centurion™

A Better Alternative To Labyrinth Seals

Eaton’s Centurion Improved Brush Seals are very high tip speed, high temperature seals, usually applied in the secondary and tertiary flow paths in gas turbine engines, capable of surface speeds up to 1,100 f/s (feet per second) and withstanding temperatures up to 1,200°F (648°C). As a replacement for labyrinth leals, brush seals evidence 20% to 40% less leakage while their bristles are in optimal condition. In addition, Centurion Improved Brush Seals weigh far less than labyrinth seals and take less axial cavity space.

Eaton’s Patented Design Increases Bristle Life

Eaton’s patented design holds the bristle pack in place, preventing deformation and stiffening, common problems affecting the longevity of the traditional brush seal. This design allows the seal to last longer at an optimal sealing performance than ordinary brush seals.

Benefits for using the Centurion Improved Brush Seals

- Better seal, means more efficiently operating motor = improved Mean Time Between Repair (MTBR)

- The better seal means fuel efficiency, with up to a .4% specific fuel cost savings as indicated by research (AIAA – Mahler and Boyles, 1995)

- Far less weight

Capability Ranges

Operating Pressures: 100 psid (690 kPa) per stage

Temperature: Cryogenic to 1,200°F (650°C)

Surface Speeds: Static to 1,100ft/s (335m/s)

Radial Excursions: Up to 0.030in (0.76mm)

Sizes: 2 in. to greater than 40 in. (.05-1.0 meters); larger diameters for segmented seals